Description

| Numbering | YT101 | Type | Rock Arm |

| Specification | 18 Tons | Material | Q345B |

| Color | Consistent with the original | Brand | BUTAMACH |

| Model | YT40 |

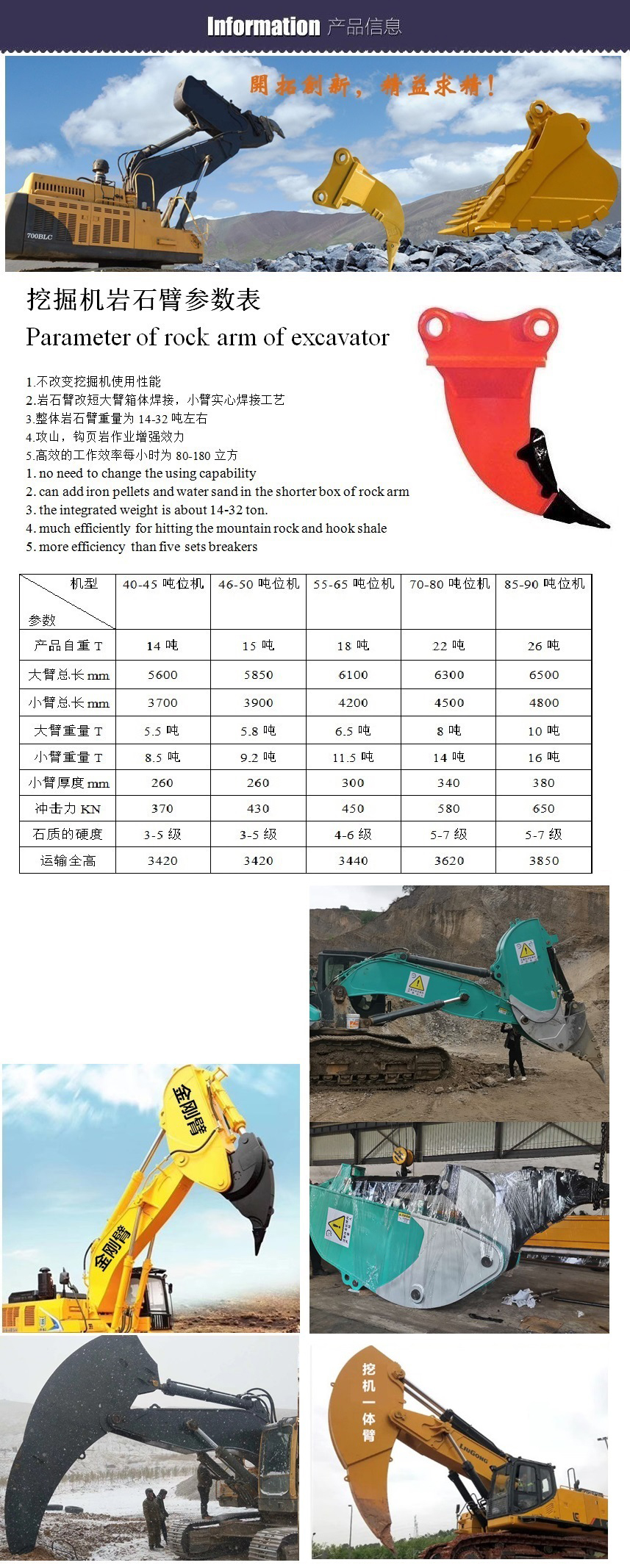

Excavator rock arm, super arm, integrated arm, eagle hook arm, hook arm, eagle hook, diamond arm, super hook modification

The company specializes in excavator rock arm modification factory, excavator diamond arm, excavator hook arm, integrated hook arm modification, etc. It is designed and customized according to customer needs. The designed product has a dead weight of about 14-32 tons. Fossils, weathered rocks and other rocks; compared with traditional breakers, it has high operating efficiency, low cost and less environmental pollution. Professional mining of weathered stone, shale, sandy limestone, fault rock, apatite, red sandstone, fluorite, syenite, etc., hard soil, coal mine and other engineering mining, effectively saving time and improving work efficiency.

1. Integrated arm hook machine: It is mainly the design of the forearm that has been changed from the old box-type welded rock arm to the current integrated arm design. More durable and rough. The weight of the forearm of different models is designed to be 8-22 tons, and the thickness of the plate is between 260-420. The boom is connected by box candles without counterweight iron sand. The working dead weight of the rock boom is designed to be 6-14 tons according to different models. The thickness of the plate is between 30 and 50. The weight of the design product is determined by the size of the model. Due to the special setting of the modified product for the hardness levels of different mines, it can achieve the ideal impact crushing effect. The integral design improves the product quality as a whole and changes the working efficiency. The main advantages of the excavator integrated arm are: extremely low failure rate, higher working efficiency, and 2-4 times higher than the overall working efficiency. Create higher productivity for guests using the product.

2. King Kong arm of excavator:

As a special attachment of the excavator, the rock arm is an environmentally friendly product for excavating and crushing weathered stone, shale rock, red sandstone, etc. It has the advantage of low loss compared with the traditional breaker operation. High efficiency, low excavation cost and low maintenance cost.

Due to the harsh working environment, in the use of materials, we use q355b\q550d materials to choose from, the thickness of the material, I will not give a detailed introduction here, the material thickness of the rock arm is about 30-45 thick.

In the welding process, we carry out multi-layer stitch welding, and an internal buffer plate is installed in the arm to withstand the tension load. After the external welding process is completed, the inside of the large and small arms is poured into the iron sand cover plate for welding, and the internal structure of the box is solid. body, further ensuring the durability of the arm.

At the same time, according to the working conditions of the mine, the single hooks we configure are all reinforced rock single hooks, which can have the effect of being indestructible. The design of the forearm cancels the general method of the connecting rod, so that the bucket cylinder directly drives the small hook, which is large and less powerful. The joints of the connecting rods are worn out, also known as super arm, diamond arm.

1. The modified rock arm of the excavator does not change the performance of the original excavator. After modification, the product is infinitely powerful.

2. The modified model with hook rock arm is (40t to 120t) ton excavator for modification

3. In the operation of the integrated rock arm, the product is more durable, the force is large and the efficiency is high.

4. The cylinder and bucket cylinder oil circuit confluence configuration in the integrated rock boom design, fast speed and strong force (the slope cannot be trimmed)

5. The design of the diamond arm is different from the integrated arm. The forearm design box is widened and enlarged, connected to the outside of the big arm, and the working weight of the forearm is increased.

6. Configure the small hook to directly connect the bucket cylinder, the small hook plate surface is thickened and equipped with d11 forged tooth root, and the hook digging angle can be adjusted to repair the slope

7. The modified product has good work efficiency, and the output per hour is about 130-260 cubic meters

8. Safe operation, high work efficiency, and provide you with higher production efficiency

9. Friends who have modified the big and small arms of the excavator are welcome to see the construction effect at the construction site or negotiate business with the factory

Customized models such as: Carter, Hitachi, Hyundai, Doosan, Volvo, Sany, Xugong, Liugong, Lovol and other large hooks to modify products