Excavator Eagle hook arm -- New Super King Kong arm

2020-04-30

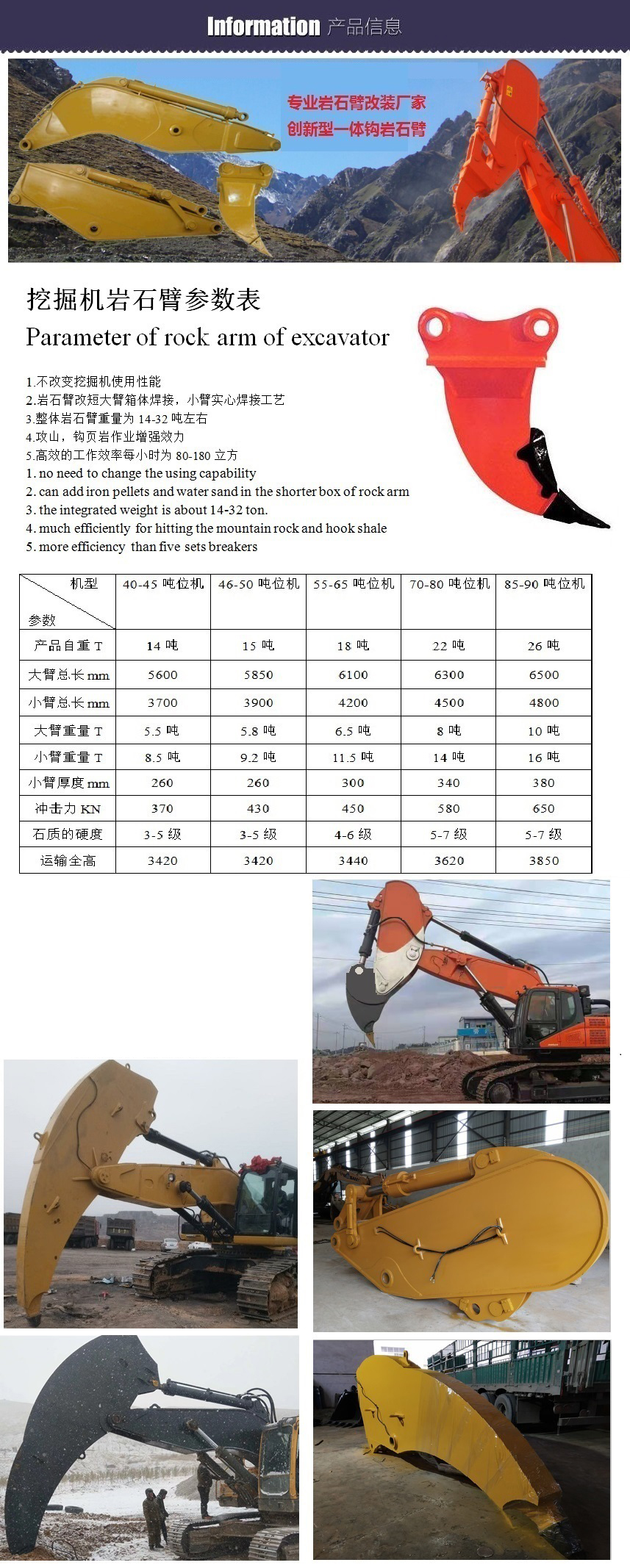

The company specializes in the production of rock arm of excavator, shortened arm of excavator, large and small arm of heavy rock, integrated arm of hook machine, rock drilling arm, integrated hook rock arm, Eagle hook modification and other different terms; Customized according to the needs of customers, the designed product has a self weight of about 14-32 tons. It is the artifact of excavating weathered fossils and shale rocks. At present, such products are mostly used in the excavation of weathered rocks in Northwest China. Compared with traditional operations, they have high efficiency, low cost and less environmental pollution. Professional excavation of weathered rock, shale, sandy limestone, fault rock, apatite, red sandstone, fluorite, syenite, hard soil, coal mine and other engineering mining, effectively saving time and improving crushing efficiency.

1、 New type rock arm of hook machine: it mainly changes the design of the small arm, from the old box type welded rock arm to the current one-piece arm. It is mainly cut and formed from the whole steel plate to complete an integrated independent product, without welding the box to load iron sand. The weight of the jib of different models is designed to be 8-22 tons \ the thickness of the plate is 260-420. The jib is connected by box candle without counterweight iron sand. According to the working weight of the rock jib of different models, the weight of the product is designed to be between 6-10 and the thickness of the plate is between 30-50. The weight of the product is designed according to different models. Because the modified products are specially designed for different levels of rock hardness in different mines, so as to achieve the ideal impact crushing effect, With the integral design, the overall product quality is improved and the working efficiency is changed. The main advantages of the excavator integrated arm are: extremely low failure rate, higher working efficiency, and improved working efficiency to 1.5-2 times speed. Create higher work efficiency for customers who use the products.

2、 Rock arm of split hook machine: due to the harsh working environment, we use Q345B \ Q550D materials for the use of materials. I won't introduce the thickness of the materials in detail here. The material thickness of the rock arm is about 30-45 thick

In terms of welding treatment, we carry out multi-layer overlap welding. Internal buffer plates are installed in the arms to bear tension loads. After our external welding processing is completed, we pour iron sand into the large and small arms to seal the cover plates for welding. The internal structure of the box is a solid body, which further ensures the durability of the arms.

At the same time, for the operation of the mine, the single hook configured is a reinforced rock single hook, which can have an invincible effect.

1. The rock arm of the hook machine is modified without changing the service performance of the original excavator

2. The rock arm of the hook machine is equipped with a modified model of (36-120) tonnage excavator

3. Rock boom is changed into short boom box welding, and the boom is solid welding process

4. The weight of the overall rock arm is about 14-32t

5. The middle cylinder of the rock arm of the hooking machine is configured in confluence, with fast speed and strong strength

6. The refitted rock arm has strong and effective rock breaking operation

7. High efficiency: 90-180 cubic meters per hour

8. Safe and efficient operation, providing you with higher work efficiency

9. Welcome customers and friends to our company for inspection and business negotiation

Customized models such as: Carter, Hitachi, Hyundai, Doosan, Volvo, Sany, XCMG and other large and medium-sized hook machines to modify the integrated arm, rock size arm, single hook modification, excavator Eagle hook, rock arm integrated hook, integrated arm hook machine, hook machine integrated arm, excavator modified arm and so on

Professional crushing of grade 3-7: weathered stone, shale, sandy limestone, fault rock, apatite, red sandstone, fluorite, syenite, etc

Comparison of new and old rock arms

As a special accessory of excavator, rock arm is a sharp tool for excavating and crushing weathered rock, shale rock and red sandstone. It has the advantages of high efficiency and low loss compared with traditional crushing hammer operation. Compared with traditional blasting operation, it has high operation efficiency, low crushing cost and low maintenance cost.

The main structure of the rock arm is the huge beak like forearm, so it is also called the beak arm. Compared with ordinary excavator, the boom is thickened and weighted to cope with stronger impact. The crushing principle of the rock arm is that under the gravity of the heavy big and small arms, the sharp hook at the front end is used to violently crush the rock, with a devastating efficiency.

At present, an integrated rock arm has appeared in the market. Compared with the traditional rock arm, this integrated design cancels the bucket cylinder and connects the jib with the Ripper, so that the forearm forms an integral arm.

Advantages of integrated rock arm:

1. The jib is cut from a whole piece of high-strength manganese steel, reducing welding and processing, and the cost is high.

2. The boom is no longer a solid boom, but a hollow reinforced boom, which reduces the weight and reduces the overall performance loss of the excavator.

3. The innovative design of the integrated rock arm combines the oil circuit of the bucket cylinder and the stick cylinder into the pipeline of the stick cylinder, increases the overall flow of the stick cylinder, improves the strength of the stick cylinder, and increases the speed under certain conditions. Without changing the overall hydraulic system of the excavator, the loss is lower and the strength is greater.

4. The plate thickness of the jib of the integrated rock arm is 26 to 36 cm according to the size of different models, which can adapt to worse working conditions without quality problems and increase the service life of the rock arm.

5. The scarifier, shaft linkage and other structures are eliminated, which makes maintenance easier, the failure rate is lower, and the driver is more relaxed.

Comparison between integrated rock arm and traditional rock arm:

1. On the surface, the old rock arm has one more action and is more flexible. In actual work, however, due to the structural limitations of the Ripper, the depth is limited when excavating rocks with low hardness; When digging hard rock, the ripper is easy to break. The one-piece rock arm replaces the jib and Ripper with a whole steel plate. Although some flexibility is sacrificed, the problem of "soft rock arm cannot dig deep and hard rock arm is easy to break" is completely solved.

2. The bucket cylinder of the old rock arm only plays a supporting role. The integrated arm cancels the bucket cylinder and connects the oil pipe of the bucket cylinder to the stick cylinder, which greatly improves the strength and speed of the stick cylinder.

3. In terms of the working principle of the equipment, both the traditional rock arm and the integrated arm increase the self weight to improve the destructive power of the Ripper. To put it simply, the heavier the weight, the more it can be pressed. The weight of the old rock arm is mainly concentrated on the boom, and the weight of the integrated arm is mainly concentrated on the jib. Most of the weight of the boom will be transmitted to the vehicle body through the lifting cylinder, and only the weight of the jib can be effectively transmitted to the force point at the front end. In other words, the design of this one-piece arm makes the weight distribution more reasonable, so as to achieve better operation results.